Intel Corporation’s operations management (OM) strategy focuses on supporting product development as the basic factor in the 10 strategic decision areas. Operations managers deal with these 10 strategic decisions for the purpose of optimizing organizational processes and productivity. As a leading semiconductor business, Intel already maintains optimized operations that suit strategic objectives. The company’s efficient semiconductor fabrication processes are an indicator of operations management success. A testament to this operational success is Intel’s attractiveness as one of the major global fabricators of chips for other firms. However, the company needs to continue evolving to address rapid market changes associated with rapid technological advancement and obsolescence. Successful operations management supports Intel’s evolution and product development via the 10 critical decision areas. While the company has high productivity, changes in market conditions impose challenges that require operational adjustments. Intel’s operations management implements these adjustments through computer-assisted decision-making processes.

Operations management needs in its global semiconductor business pushes Intel to find new ways to optimize efficiency and productivity. As a technology business, the company takes advantage of its technology-savvy human resources to successfully maintain automation to support operations managers’ activities. Through these efforts and a constant monitoring of the global market, Intel remains effective in the 10 strategic decision areas. Such effectiveness depicts continuous success and long-term leadership in the industry.

Intel’s Operations Management: 10 Decision Areas

1. Design of Goods and Services. Intel’s mission statement and vision statement guide operations management decision-making in this strategic decision area. The company’s objective in this area is to produce profitable and excellent output that satisfies market demand. For example, Intel’s corporate vision and mission emphasize leadership in bringing semiconductor products to every customer around the world. This aim is achieved through microprocessors and other products designed with cutting-edge technologies and distributed globally. Intel’s operations management supports these activities through cost minimization and resource planning to optimize the impact of product designs on organizational stability.

2. Quality Management. The determination and satisfaction of quality expectations are the objectives in this strategic decision area. Intel’s operations managers evaluate quality expectations through market research and feedback from customers, sellers, and distributors, among others. The data is used as a basis for implementing adjustments in operational policies. For example, to address concerns regarding defects, adjustments are made in Intel’s operations management policy on margins of error. Such action supports optimal productivity while addressing quality issues. Operations management effectiveness in this strategic decision area aligns with Intel’s generic competitive strategy and intensive growth strategies.

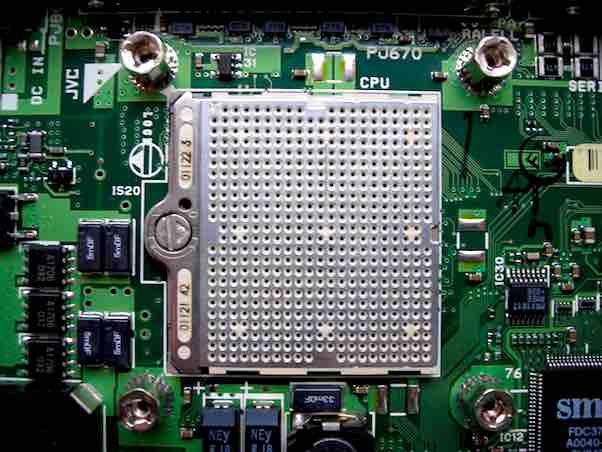

3. Process and Capacity Design. Operations managers’ objective in this strategic decision area is to maintain processes through standards compliance and resource adequacy to support productivity goals. In the case of Intel Corporation, such goals are achieved through process automation. As part of the company’s operations management, reviews are regularly conducted on available technologies and related resources to determine capacity statuses and requirements. For example, operational capacity levels are evaluated to develop corresponding solutions to optimize Intel’s operational productivity in its microprocessor fabrication plants. These efforts in operations management ensure high-efficiency processes and advantageous economies of scale, which are among the strengths highlighted in the SWOT analysis of Intel Corporation.

4. Location Strategy. Cost-optimal distances from target markets, suppliers, and resources are the objectives in this strategic decision area of operations management. Intel’s approach to achieve these objectives focuses on human resources and logistics. For example, the company prioritizes access to talent necessary to maintain the competitive advantage of its semiconductor business. Nonetheless, to complement this situation, distributor locations are optimized for maximum reach in target markets. These locations are included in Intel’s marketing mix or 4P. The approach ensures the company’s operations management effectiveness in this strategic decision area.

5. Layout Design and Strategy. Intel aims to maximize efficiency of the flow of resources and information to address this strategic decision area. Through such maximization, the company’s operations management supports high productivity. Intel fulfills this aim by using office layouts that facilitate efficient work and creativity. For example, the company’s office layouts make it easy for employees to meet and share creative ideas for new product development. Also, many characteristics of layouts, including processor fabrication plant layouts, are based on Intel’s organizational structure (company structure). Any new product line requires new spaces, layouts, and corresponding components in the corporate structure. This approach shows that Intel’s operations management in this strategic decision area is flexible to accommodate changes linked to business growth and expansion.

6. Job Design and Human Resources. In this strategic decision area, the main objective is to maintain adequate human resources to support operational efficiency and productivity goals. Intel satisfies this objective through an operations management approach that primarily involves human resource management. For example, the HR strategy involves job designs that support Intel’s organizational culture (corporate culture), which emphasizes discipline, results orientation, and other factors. Also, the company has productivity enhancement measures, such as leadership development programs and seminars for better employee output. Thus, Intel’s operations management addresses the aims in this strategic decision area.

7. Supply Chain Management. A high-efficiency and adequate supply chain is the objective in this strategic decision area of operations management. In Intel’s case, the supply chain is automated to maximize efficiency. For example, the company has computer systems and databases for monitoring and determining areas that need immediate adjustment. In addition, Intel’s operations management efforts influence suppliers through policies that extend to their business activities. For instance, the company develops and implements policies to improve the sustainability and environmental impact of the entire supply chain, inclusive of suppliers and other relevant organizations. These operations management efforts are part of Intel’s corporate citizenship strategy for stakeholders and CSR and ESG goals. These efforts are also partly responsible for the company’s high operational productivity and economies of scale that contribute to Intel’s competitive advantage in the semiconductor industry.

8. Inventory Management. Intel’s operations managers are concerned with inventory holding and ordering to support business productivity goals. The objective is to ensure that the inventory satisfies capacity requirements alongside market demand. Intel’s operations management approach for this strategic decision area involves a serialized inventory and the “first in, first out” (FIFO) method. For example, the FIFO method addresses issues with technological obsolescence, especially with regard to intermediate products in semiconductor fabrication processes. Correspondingly, serialization allows Intel to track every item in its inventory. The resulting combination ensures the company’s efficiency and effectiveness in satisfying changes in market demand. This operations management approach supports increasing R&D investment, which is a significant technological external factor, as noted in the PESTLE/PESTEL analysis of Intel Corporation.

9. Scheduling. In operations management, the objective in this strategic decision area is to establish short-term and intermediate schedules that satisfy market demand. An appropriate approach in Intel’s case involves short-term schedules for immediate concerns and generalized schedules for regular processes. For example, the company uses short-term schedules for microprocessor fabrication processes involving batches or projects. On the other hand, generalized schedules are for regular processes, like equipment maintenance and product development iteration. This approach ensures that Intel’s operations management and productivity efforts satisfy dynamic needs and relatively constant needs in the semiconductor business.

10. Maintenance. Process stability and reliability are the objectives in this strategic decision area of operations management. Intel has a multi-pronged approach to ensure effective solutions for these concerns. For example, operations managers coordinate with HR management teams to maintain an adequate workforce. In addition, Intel supports high operational productivity by maintaining cutting-edge technologies, such as equipment used to fabricate semiconductor chips. Another operations management approach involves high R&D investment to maintain technological competitive advantages, which address the external force of competitive rivalry described in the Five Forces analysis of Intel Corporation.

Productivity at Intel

Considering its global business and a growing product mix, Intel Corporation uses various sets of measures and criteria for evaluating productivity. Some of these criteria refer directly to individual employee output, while others measure group or organizational productivity to guide operations management decision-making. The following are some of the quantitative productivity metrics applicable to Intel:

- Batches produced per day (Fabrication productivity)

- Problem tickets processed per day (Customer service productivity)

- Units delivered per month (Distribution productivity)

References

- Gao, L., & Huang, R. (2024). Digital transformation and green total factor productivity in the semiconductor industry: The role of supply chain integration and economic policy uncertainty. International Journal of Production Economics, 274, 109313.

- Garrido, S., Muniz Jr, J., & Ribeiro, V. B. (2024). Operations management, sustainability & industry 5.0: A critical analysis and future agenda. Cleaner Logistics and Supply Chain, 100141.

- Intel Corporation – Form 10-K.

- Intel Corporation – Operating Segments.

- Intel Corporation – Supplier Corporate Responsibility.

- Mourtzis, D., & Sgarbossa, F. (2024). Operations management and information systems for smart manufacturing. In Manufacturing from Industry 4.0 to Industry 5.0 (pp. 267-288). Elsevier.

- Yu, Y., Ma, D., & Wang, Y. (2024). Structural resilience evolution and vulnerability assessment of semiconductor materials supply network in the global semiconductor industry. International Journal of Production Economics, 270, 109172.