General Electric Company (doing business as GE Aerospace) maximizes productivity in the 10 critical decision areas of operations management through strategic technological integration. This OM approach involves reliance on advanced technologies for competitiveness in multinational aerospace business. For example, GE uses digital technologies as solutions to operational issues. In operations management, the 10 critical decisions specify strategic objectives for the main areas of operations. In this case, General Electric applies various strategies and tactics suitable for its industry. The company’s operations managers implement industry-specific strategies and tactics, as well as organization-wide policies for OM. As a major global aerospace firm, GE’s operations management strategies affect markets through technological solutions provided to client firms. Pertinent to General Electric’s mission statement and vision statement, this condition emphasizes the significance of operations management decisions in developing the aerospace business.

Employees use General Electric Company’s operations management strategies and tactics as signals for adjustments in individual job performance. For example, a change in GE’s productivity targets for one of the 10 strategic decision areas of operations management may affect some or all areas of operations. Employees adjust their job activities, accordingly. While General Electric has programs for change management, operations management helps align human resource activities with the changing operational targets of the global aerospace business.

GE’s Operations Management, 10 Critical Decisions

1. Design of Goods and Services. GE’s objective in this decision area of operations management is consistency in costs and quality in producing aerospace goods and services. General Electric Company’s approach prioritizes high quality standards, while cost considerations come second. GE also uses advanced digital technologies to facilitate consistency in operations and productivity in this strategic decision area of operations management. However, because General Electric’s corporate structure (business structure) is divisional, operations management applies divisional policies specific to product type and design. For example, GE Aerospace has different quality and cost consistency approaches between its Commercial Engines and Services division and its Defense and Systems division. Thus, high operational efficiency is achieved while ensuring the flexibility of General Electric’s global business in addressing product-specific and market-specific challenges.

2. Quality Management. In this critical decision area of GE’s operations management, the objective is to ensure that aerospace product quality satisfies the company’s standards and customers’ expectations. General Electric implements market research to determine such expectations. Multiple research campaigns cover the market environments of GE. For example, research on customers’ quality expectations about General Electric avionics systems informs the company’s operations management, and research in the transportation sector guides managers in the company’s operating quality decisions. The resulting quality management guidelines align with General Electric’s generic competitive strategy and intensive growth strategies, which emphasize high quality and advanced technological features. Such guidelines facilitate operational effectiveness in meeting quality and productivity targets in GE’s business.

3. Process and Capacity Design. The objective in this decision area is to strategically align aerospace operations management with production goals, with consideration for resources. In General Electric’s case, these resources include technological resources and human resources, among other resources. Technologies define much of GE’s processes and production capacities. For example, the company uses digital technologies to optimize efficiency in its operations in the avionics market. Technological emphasis at General Electric Company requires operations management to set productivity goals through automated tools for maximizing operational efficiency. In this way, operations management for process and capacity design helps minimize constraints in the multinational aerospace business.

4. Location Strategy. This strategic decision area of aerospace operations management deals with the physical location of facilities. In this case, the objective is to reach General Electric Company’s operational targets through optimal strategies for supply chains and target markets. The company has multiple supply chains and locations because of the diversity of its business operations. For example, based on General Electric’s marketing mix (4P), the same region may have different and coexisting locations for the firm’s operating segments. In this regard, GE’s location strategy is mainly based on product-specific and market-segment operational goals. Operations management addresses the unique demands of each division or market segment. This condition contributes to business resilience against competitive rivalry with Pratt & Whitney, Rolls-Royce, and other firms assessed in the Five Forces analysis of General Electric Company. GE’s locations are strategically determined based on resource accessibility and market proximity. Productivity goals vary according to product or market segment.

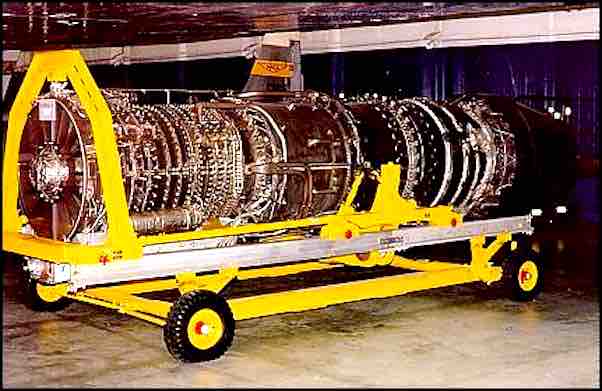

5. Layout Design and Strategy. GE’s strategic objective in this critical decision area is to apply operations management principles to optimize workflows and material flows in aerospace business. General Electric’s operations management applies the principles of leanness. Lean thinking, lean manufacturing, and lean management in layout design maximize GE’s operational efficiency and productivity. For example, the company’s lean layout design in turbojet engine manufacturing contributes to profit maximization through production efficiency. In addition, General Electric’s layout design and strategy support employee productivity and empowerment in the workplace.

6. Job Design and Human Resources. In this decision area of General Electric’s aerospace operations management, the objective is to maintain an adequate and effective workforce through suitable human resource management strategies. General Electric’s organizational culture (corporate culture) plays a significant role in this area. For example, the company’s cultural support for learning and adaptation contributes to workforce capabilities for fulfilling aerospace business goals. Also, to facilitate HR development, GE has continuous improvement programs that push for productivity and innovation throughout the business organization. Operational tactics applied in this critical decision area affect General Electric’s corporate social responsibility (CSR) and ESG strategy and stakeholder management, which rely on human resource support through appropriate training and employee involvement.

7. Supply Chain Management. GE’s operations management objectives in this decision area are to streamline operations for cost effectiveness and to maintain stable aerospace business partnerships with suppliers. Operating strategies applied in this area contribute to General Electric’s competitive strengths necessary for addressing rivalry affecting the multinational business, as shown in the SWOT analysis of General Electric Company. To address these concerns, General Electric implements digital technologies to improve suppliers’ decision-making processes for GE’s supply chain reliability. In addition, the company’s supplier diversity program helps minimize the risk of overdependence on just one or a few suppliers. Also, operational streamlining is achieved through advanced digital technologies at General Electric. In applying these strategies, operations management considers the external trends discussed in the PESTLE/PESTEL analysis of General Electric Company. For example, the company’s operations management considers technological trends and uses advanced technologies to increase overall business productivity.

8. Inventory Management. This strategic decision area of General Electric Company’s operations management deals with inventory control. The objective is to maintain adequate inventory for the aerospace business. General Electric’s operations management uses digital tools in managing inventory. For example, the company has centralized business information systems for managing inventory throughout its aerospace design and manufacturing operations. These systems automate many aspects of inventory management and enable GE to increase productivity through operational efficiency. Thus, technological tools characterize General Electric’s approach in this critical decision area.

9. Scheduling. GE’s objective in this strategic decision area of operations management is to achieve aerospace operating targets despite constraints on time and resources. General Electric Company has a large variety of schedules because of its operations in different markets involving the aerospace industry. Each scheduling approach considers the challenges in the corresponding operating division or market segment of GE. For example, the scheduling policy for avionics operations addresses inventory management and productivity challenges that General Electric faces in the market composed of commercial airlines, like Southwest. In addition, GE’s operations management applies schedules based on relevant factors, like geographic characteristics and local business conditions. These variables require operational flexibility that suits the different markets and products of General Electric’s global business.

10. Maintenance. In this strategic decision area, General Electric’s objectives include maintaining production quality, process consistency, and resource reliability. For example, operations management is tasked with maintaining reliable technological resources that support General Electric’s multinational business. The company’s operating policies require regular monitoring and upgrades for technological resources, such as business information systems. In addition, GE’s operations management strategy maintains productive processes through strict monitoring and control of workflows. Human resource training and product design also influence the effectiveness of the maintenance of General Electric Company’s processes.

Productivity at General Electric Company

Productivity at General Electric is evaluated using different sets of criteria or metrics that represent the operating divisions of the global aerospace business. For example, productivity in the Commercial Engines and Services division is measured based on the quantity and quality of aircraft engines and services provided to GE’s customers. General Electric’s operations management strategies in the 10 decision areas also affect the types of productivity criteria applied to support the decisions of corporate managers. Considering operational variations, the following are some of the notable productivity metrics applicable in General Electric Company’s operations:

- Batches shipped per day (productivity of GE’s supply chain)

- Engines delivered per year (productivity of GE distribution and sales)

- Projects completed per quarter (productivity of General Electric’s services)

References

- GE Aerospace Investing in Manufacturing.

- GE Aerospace Safety and Quality.

- General Electric Company Form 10-K.

- Hafidy, I., Benghabrit, A., Zekhnini, K., & Benabdellah, A. C. (2024). Driving Supply Chain Resilience: Exploring the Potential of Operations Management and Industry 4.0. Procedia Computer Science, 232, 2458-2467.

- Holopainen, M., Saunila, M., & Ukko, J. (2024). The effects of digital business strategy on the collaboration performance of companies: The moderating effect of digitally enabled performance measurement. International Journal of Industrial Engineering and Operations Management, 6(1), 64-81.

- Léonard, P. L., Hallstedt, S. I., Nylander, J. W., & Isaksson, O. (2024). An Introductory Study of the Sustainability Transition for the Aerospace Manufacturing Industry. In Sustainable Production through Advanced Manufacturing, Intelligent Automation and Work Integrated Learning (pp. 577-588). IOS Press.